In the development process of cosmetics, after confirming the material body and design plan and other related matters, and then entering the development of packaging materials, purchasing personnel need to face many packaging material choices and communicate and coordinate with many suppliers.

When faced with opening private models and carrying out private customization, this kind of communication will become relatively complicated, because when it comes to technical issues, it will be difficult to coordinate with several different suppliers.

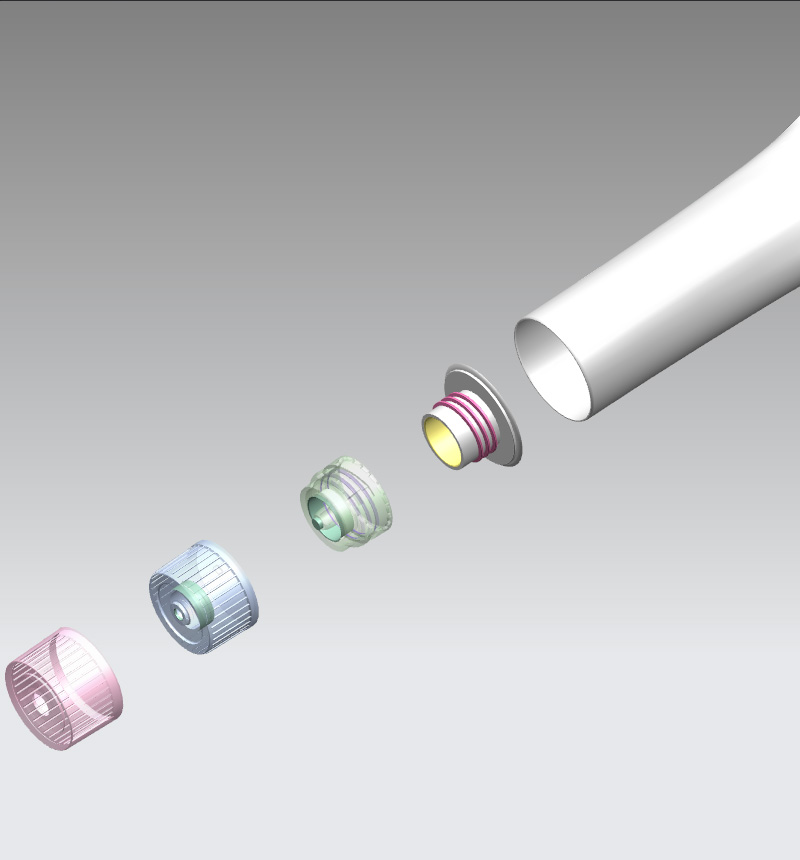

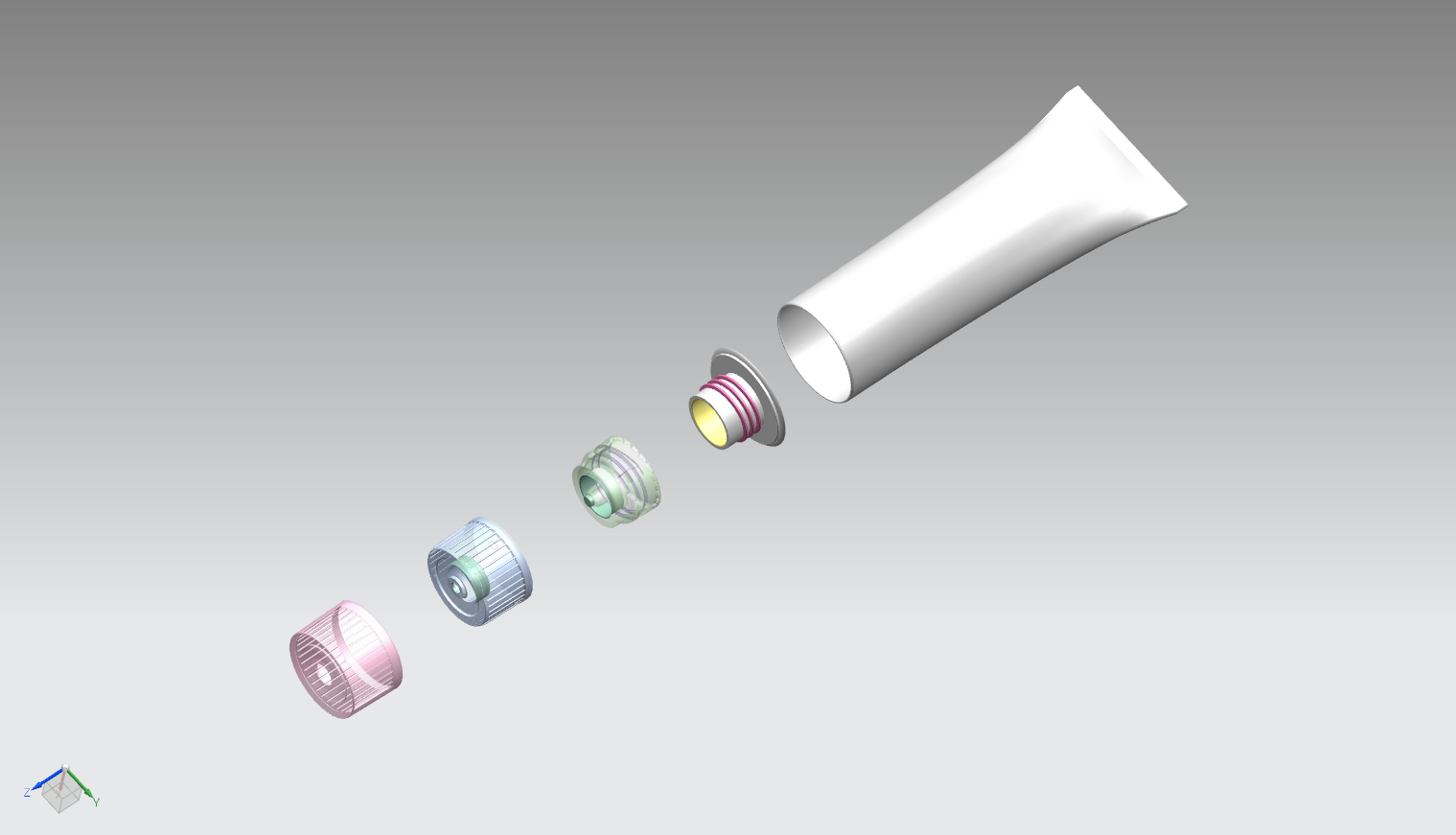

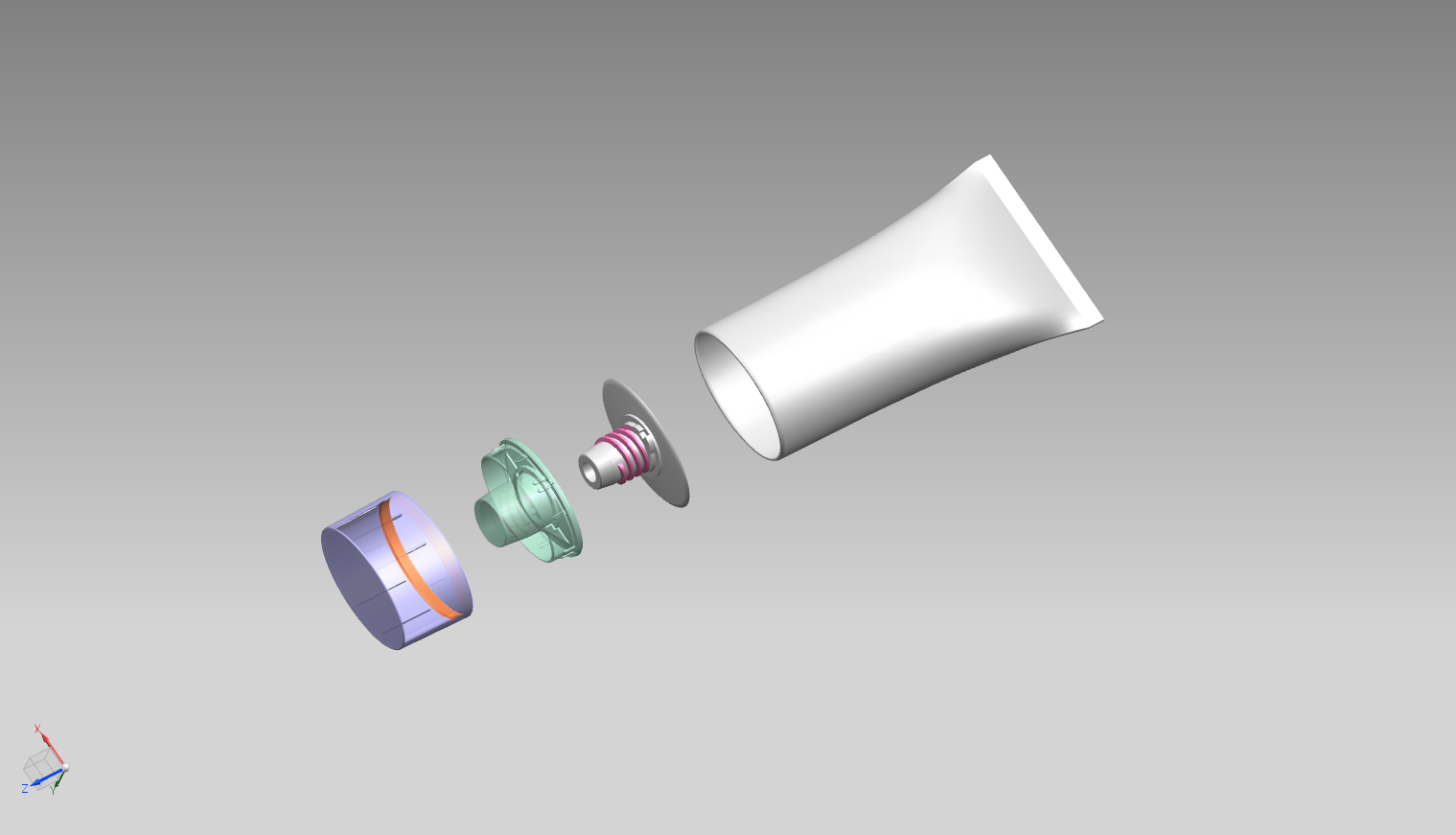

For example: when it is necessary to develop special-shaped vials and caps, after giving the shape design plan, coordinate at the same time. Cap manufacturers, hose manufacturers, and bottle manufacturers need to refine the relevant matching structure and matching dimensions, so several processing units are needed. The design company and the client communicate and negotiate together. If the order is for international trade, the problem of time difference needs to be solved, and the efficiency and accuracy will be greatly reduced.

Original scene: customer + trading company + design company + hose factory + bottle factory + cap factory (mold factory)

Such a model leads to long development time of packaging materials, poor communication, prone to technical problems, and in the future production process, prone to mismatch problems, and it is more troublesome to trace back.

New scene: customer + source factory

(Factory: capable of design, mold development, bottle, hose, cap production capacity)

With such a new model, customers only need to connect with the comprehensive development department of the source factory, and the development department will connect with each department to provide the final solution and products to the customer. One-to-one connection is efficient and less error-prone.

product design:

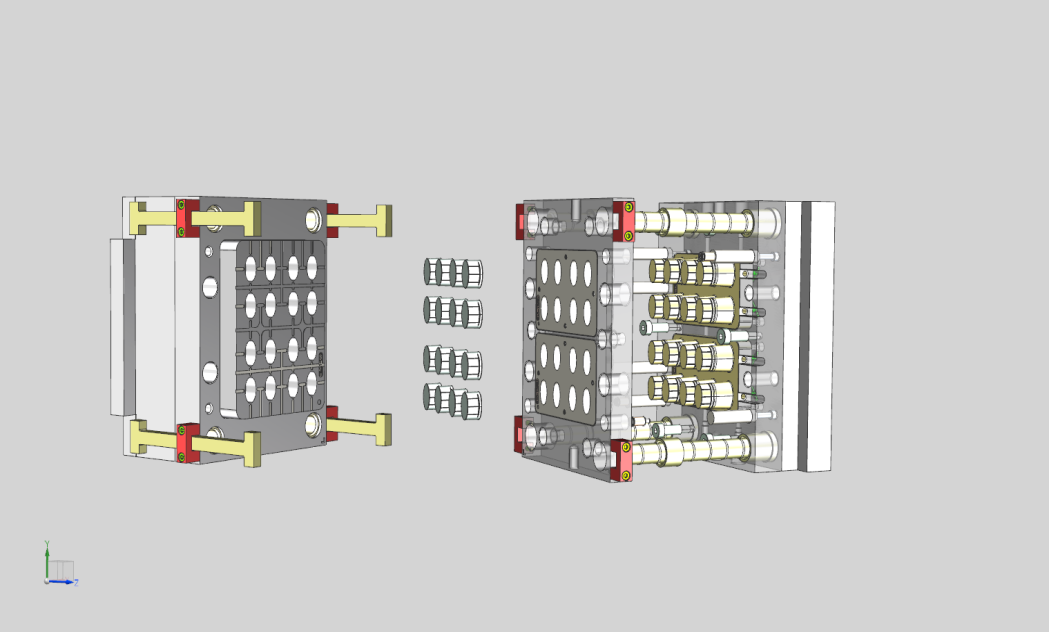

Mold design and manufacturing

Bottle (tube) / cap production

Assembly/finished product

From the customer's idea--scheme design--mold making--packaging material production--assembly according to customer demand--customer inspection--delivery according to demand, so as to provide one-stop smooth service, solve customer pain points, and efficiently , low cost, and bring a good customized experience to customers.

Zhenggao company has design ability, mold development and manufacturing ability, bottle and tube production capacity, and has been committed to two-color injection molding of cosmetic caps for many years. It has independently developed a variety of two-color caps, and at the same time provides customers with technical support for two-color caps and innovative bottle types Service is the preferred choice for the international trade of cosmetic packaging materials.

Foshan Zhenggao Packaging Technology Co., Ltd.

2022-08-22